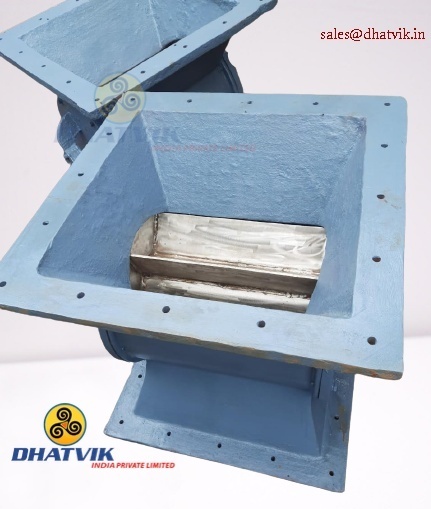

ROTARY AIR LOCK VALVE FOR CFBC BOILER

Price 20000.00 INR/ Number

MOQ : 1 Number

ROTARY AIR LOCK VALVE FOR CFBC BOILER Specification

- Material

- Cast Iron

- Inlet/Outlet Connection

- Flanged ends

- Wear Resistance

- High wear resistance for boiler ash handling

- Operation

- Motorized / Manual

- Maintenance

- Low, due to robust design

- Valve Type

- Rotary Air Lock

- Sealing

- High efficiency sealing arrangement

- Leakage

- Minimized by precision engineering

- Product Name

- ROTARY AIR LOCK VALVE FOR CFBC BOILER

- Design Standard

- ANSI / ASME

- Finish

- Paint Coated

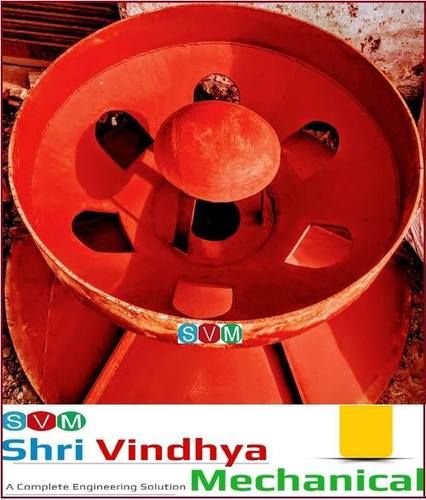

- Rotor Type

- Multi-blade, precision-fitted

- Application

- CFBC Boiler

- Mounting Orientation

- Horizontal / Vertical

- Usage

- Dust discharge, Pneumatic conveying in boilers

- Color

- Dark Blue (Standard)

ROTARY AIR LOCK VALVE FOR CFBC BOILER Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Mimbai, Kolkata

- Payment Terms

- Paypal, Cash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Western Union, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Delivery Point (DP), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 4 Per Month

- Delivery Time

- 1 - 2 Week

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Box Type

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Africa, Central America, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

- Certifications

- 3rd Party Certification

About ROTARY AIR LOCK VALVE FOR CFBC BOILER

Specification :-ID- 590 X 590MM, OD-750 X 750MM

Body Material -CARBON STEEL or Cast Iron

Rotor Material SS316

Keywords - Rotary Airlock Valve, Rotary Airlock, Airlocks, Rotary Valves, Rotary Shafts, Blades, Rotar, Water Blower, Impeller, Flipper, Rotary Feeders, Rotary Valves, etc.

High-Performance Air Lock Valve for CFBC Boilers

The Rotary Air Lock Valve excels in CFBC boiler operations, effectively managing dust discharge and pneumatic conveying with precision. Its advanced sealing system ensures optimal performance even in demanding ash-handling environments. The valve's construction from durable cast iron and corrosion-resistant paint enhances longevity, while the flexible operation modes (manual or motorized) offer tailored solutions for industrial processes requiring reliability and reduced downtime.

Designed for Wear Resistance and Minimal Leakage

Engineered with a multi-blade precision-fitted rotor and robust materials, this valve withstands the harsh conditions of boiler ash handling. The high-efficiency sealing mechanism is key to minimizing leakage, critical for maintaining process integrity and workplace safety. The standardized flanged ends comply with ANSI/ASME norms, making integration with a wide range of boiler systems straightforward for manufacturers and service providers.

FAQ's of ROTARY AIR LOCK VALVE FOR CFBC BOILER:

Q: How does the rotary air lock valve benefit CFBC boiler operations?

A: The valve provides reliable dust discharge and pneumatic conveying by minimizing leakage and enhancing wear resistance, which is essential for maintaining efficiency and extending equipment service life in CFBC boiler ash handling applications.Q: What materials and design standards are used for this valve?

A: It is manufactured from high-grade cast iron and finished with a durable dark blue paint. The valve also adheres to ANSI/ASME standards, ensuring compatibility and safety in industrial settings.Q: When should this valve be used in boiler systems?

A: The rotary air lock valve is ideal for use during continuous operation of CFBC boilers, especially where dust discharge and ash handling require robust, low-maintenance components for minimized downtime.Q: Where is the valve typically installed within the CFBC boiler system?

A: It is mounted at dust discharge points or in pneumatic conveying lines, either horizontally or vertically, to facilitate efficient airflow and material transfer while preserving system integrity.Q: What is the process for maintaining this rotary air lock valve?

A: Due to its robust design and precision engineering, the valve requires minimal maintenance. Routine inspections and occasional cleaning of the rotor and sealing surfaces are recommended for optimal performance.Q: How does the valve's sealing mechanism minimize leakage?

A: The high-efficiency sealing arrangement, combined with a precision-fitted multi-blade rotor, effectively prevents ash and dust leakage, contributing to safer and more reliable boiler operations.Q: What are the usage advantages of this valve for exporters and manufacturers?

A: Its standardized design, high durability, and adaptability for both manual and motorized operation make it a preferred choice for exporters, manufacturers, and service providers catering to the CFBC boiler industry in India and globally.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fabrication Services Category

Coal Distribution Hopper Assembly For Gasifier Unit

Price Range 2000.00 - 8000.00 INR / Piece

Minimum Order Quantity : 1 2 Number

Heavy Fabrication Work Services

Price Range 5000.00 - 8000.00 INR / Piece

Minimum Order Quantity : 1 2 Number

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese