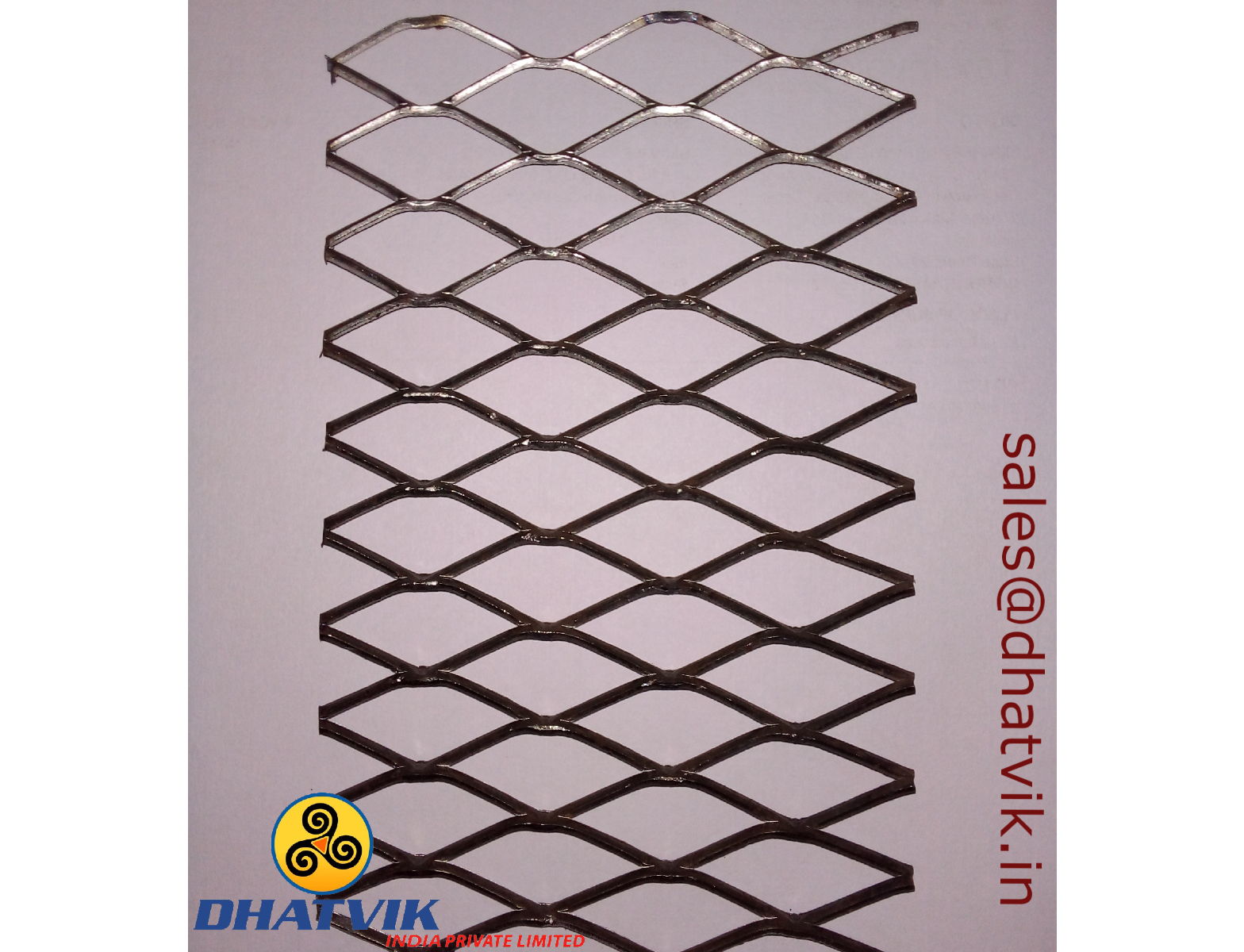

Expanded Metal Mesh, Wire Mesh

Expanded Metal Mesh, Wire Mesh Specification

- Maximum Sheet Length

- Up to 6 meters

- Delivery Condition

- As per order, immediate shipment possible

- Sheet Width

- Standard up to 2.5 meters

- Product Name

- Expanded Metal Mesh

- Packing Type

- Palletized or Rolls as per customer requirements

- Open Area Percentage

- Normally 30-75% depending on mesh design

- Color

- Silver/Grey (custom color on request)

- Compliance Standard

- ASTM, IS, or as specified

- Application

- Security Fencing, Construction, Filtration, Walkways, Grilles

- Strand Width

- Customized from 0.5mm upwards

- Usage Environment

- Indoor and Outdoor

- Sheet Thickness

- Standard 0.5mm to 8mm

- Surface Treatment

- Galvanized, Powder Coated, or Plain

- Features

- Durable, Corrosion Resistant, High Strength

- Mesh Size

- Customized (various aperture sizes available)

- Shape

- Sheet / Roll

- Type

- Wire Mesh

- Edge Type

- Raised or Flattened

- Material

- Mild Steel (MS) / Stainless Steel

Expanded Metal Mesh, Wire Mesh Trade Information

- Minimum Order Quantity

- 100 Meter

- FOB Port

- Mumbai, Kolkata

- Payment Terms

- Letter of Credit (L/C), Telegraphic Transfer (T/T), Paypal, Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 50 Per Week

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- No Need of Packaging

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

- Certifications

- 3rd Party Certification

About Expanded Metal Mesh, Wire Mesh

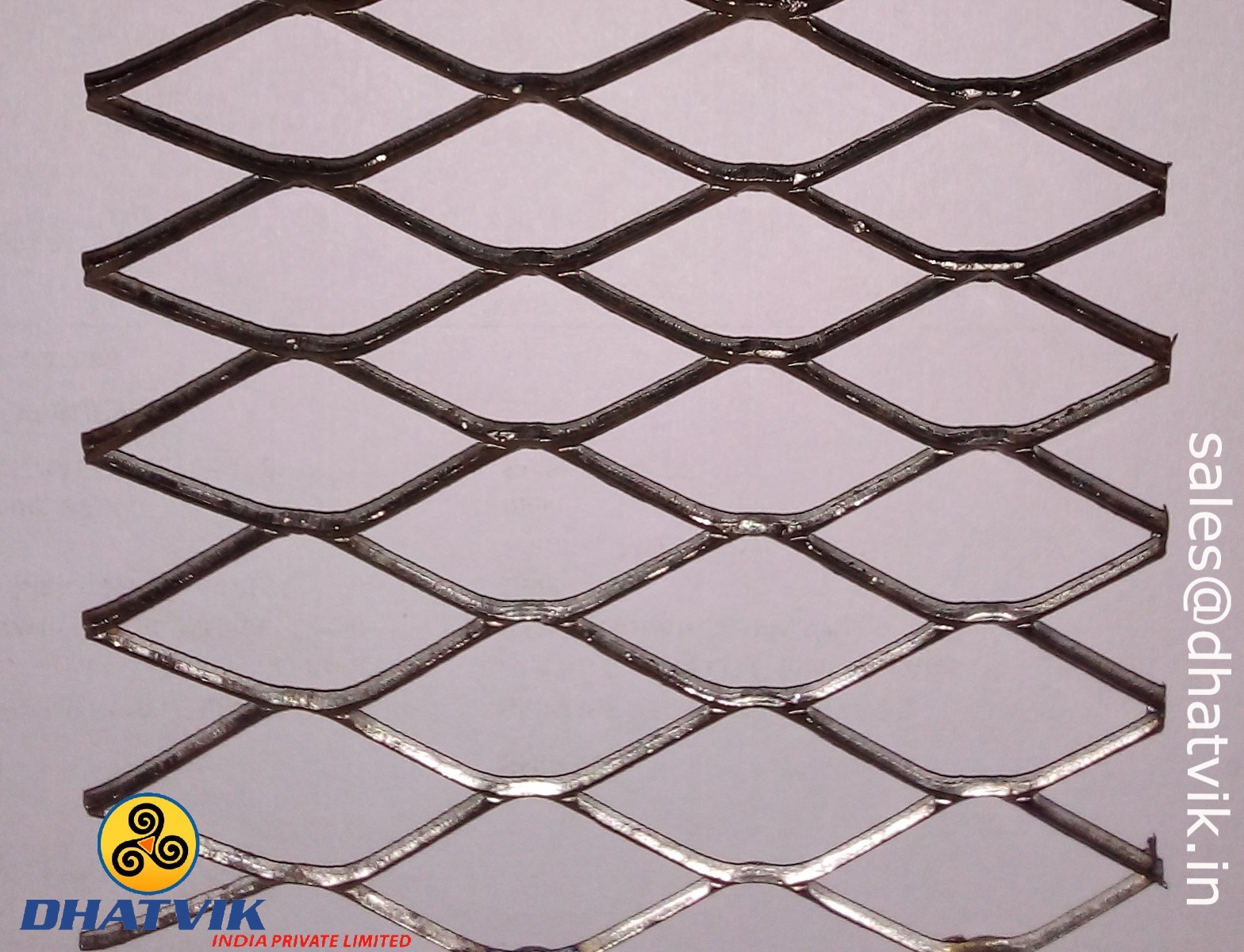

expanded metal mesh is made of a single solid sheet of compressed and stretched material. The expanded metal grating is useful for heavyweight custom parts washing applications, as well as providing open space for air flow and drainage.

Mesh of the expanded metal is uniform and does not elongate. The light and rigid mesh is strong against impact. Handling and execution are very simple, slip stopping is high, and easy execution is economical,assisted by good day lighting and ventilation.

Expanded metals in recent years are used in all fields,such as electric instruments, acoustic equipment, firing trays, automobiles, vessels, machine covers, side road protection, roads, buildings, lattices for windows,partitions, household equipment including shelves, birdcages and flower stands.

EMI shielding, ornaments, aircraft, vehicles, electric appliances, chemical equipment, mechanical equipment,filters, etc.

Expanded Metal Provides High-Security Fence Solutions.

Customizable for Diverse Applications

Expanded Metal Mesh is engineered to meet unique project requirements, offering customizable strand widths, mesh sizes, thicknesses, and finishes. This adaptability makes it suitable for a multitude of applications-ranging from security fencing and construction to filtration, walkways, and architectural features-serving both indoor and outdoor environments.

High-Strength and Corrosion Resistance

Manufactured from quality mild steel or stainless steel, and available with surface treatments like galvanizing or powder coating, this mesh ensures enhanced durability and resistance to corrosion. Its robust construction delivers excellent strength-to-weight ratio, making it ideal for demanding settings, including high-security and industrial uses.

FAQ's of Expanded Metal Mesh, Wire Mesh:

Q: How is Expanded Metal Mesh manufactured to meet different project requirements?

A: Expanded Metal Mesh is produced by slitting and stretching sheet metal, creating a mesh with customizable strand widths (from 0.5mm up), varying aperture sizes, and different thicknesses (0.5mm-8mm). This allows manufacturers to adapt mesh specifications-including edge type, sheet size, and surface treatment-to suit specific applications.Q: What are the standard and customizable options available for Expanded Metal Mesh?

A: Standard options include sheet length up to 6 meters, width up to 2.5 meters, sheet thickness from 0.5mm to 8mm, and open area percentage from 30% to 75%. Customers can choose raised or flattened edges, plain, galvanized, or powder-coated surfaces, and request custom mesh sizes and colors to fit particular needs.Q: Where can Expanded Metal Mesh be effectively used?

A: The mesh is suitable for both indoor and outdoor settings. Common uses include security fencing, construction projects, filtration systems, walkways, grilles, and architectural applications, thanks to its strength, durability, and corrosion-resistant properties.Q: What benefits does Expanded Metal Mesh provide over alternative materials?

A: Expanded Metal Mesh offers high strength, excellent load capacity, and durability, combined with good air and light passage. Its corrosion resistance (especially when galvanized or powder coated) and flexibility in design and sizing make it advantageous for various industrial, commercial, and security-related applications.Q: How is Expanded Metal Mesh delivered and what are the packing methods?

A: The mesh can be supplied in sheet or roll form, packaged either on pallets or as rolls according to customer requirements. Delivery is tailored to the order and, in many cases, immediate shipment is possible to meet tight project timelines.Q: Which compliance standards does Expanded Metal Mesh adhere to?

A: Depending on customer specifications, the mesh complies with ASTM, IS, or other relevant international standards, ensuring quality and suitability for regulated applications, both domestically in India and internationally.Q: When should I order customized Expanded Metal Mesh for my project?

A: It's advisable to order customized mesh early in your project planning stage, allowing time for specification discussions, production, and on-time delivery-especially if you need specialized sizes, treatments, or immediate shipment for urgent needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

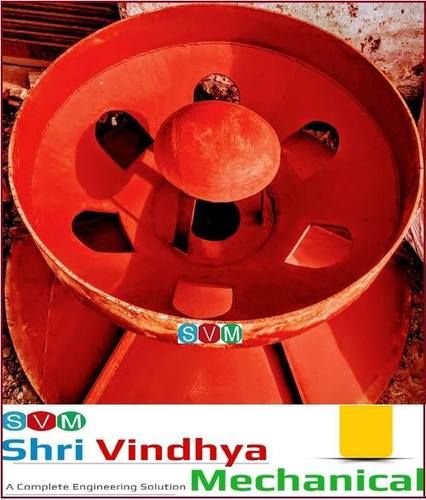

More Products in Fabrication Services Category

Fabricated Fencing, Metal Mesh Fencing, Wire Mesh Fencing, Safety Fencing

Price Range 1000.00 - 5000.00 INR / Meter

Minimum Order Quantity : 1 Meter

Coal Distribution Hopper Assembly For Gasifier Unit

Price Range 2000.00 - 8000.00 INR / Piece

Minimum Order Quantity : 1 2 Number

Heavy Fabrication Work Services

Price Range 5000.00 - 8000.00 INR / Piece

Minimum Order Quantity : 1 2 Number

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese