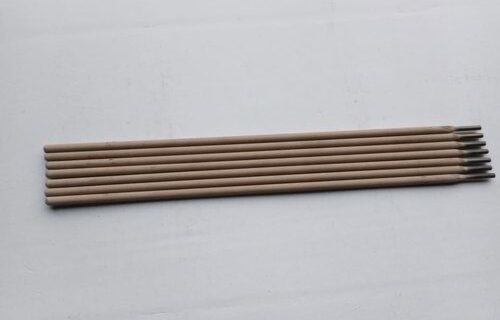

Low Heat Chromium Carbide Anti-wear High-alloy Electrode

Price 300 INR/ Box

Low Heat Chromium Carbide Anti-wear High-alloy Electrode Specification

- Material

- stainless steel

- Usage

- This special series of welding rods is designed for processing stainless steel materials such as 301, 302, 304 and 305.

- Diameter

- 2.5 - 5 Millimeter (mm)

- Opening Pattern

- AC

- Product Type

- Mechanical

- Welding Current

- 50 - 240 A

- Color

- silver

- Working Temperature

- 300 Celsius (oC)

- Length

- 350 Millimeter (mm)

Low Heat Chromium Carbide Anti-wear High-alloy Electrode Trade Information

- Minimum Order Quantity

- 1 Box

- FOB Port

- Mumbai, Kolkata

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Boxes Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Box

- Main Export Market(s)

- Western Europe, Australia, South America, Eastern Europe, Middle East, Africa, Central America, Asia, North America

- Main Domestic Market

- All India

- Certifications

- 3rd Party Test Certificate.

About Low Heat Chromium Carbide Anti-wear High-alloy Electrode

Length - 350 to 450 mm

Diameter - 2.5 to 5 mm

Welding Current - 50 to 240 A

Hardness(As Welded) - 57 - 62 HRC

Packaging Type - BoxDescription :

It is a low heat "Chromium Carbide" anti-wear high-alloy offer excellent resistance against abrasion, pressure and mild to medium impact on steel components of low alloy and manganese steels. Easy welding with self slag removal. Bright weld bead with smooth appearance. Stable arc. High recovery.

Application :

It is suitable for Sugar Cane Knives, Bull dozer blades, Crusher teeth, Pump bodies, Dredging pump impellers, Mixer blades, Scraper blades, Pulleys, Ripper teeth, Crushing & Pulverizing plants, dredger pump casings, screws, conveyors, Fibrizer/Mincer hammers, Augers screws, Rolling mill entry & exit guides etc.

Procedure:

Rebake the electrodes at 300°C for 1 hour to prevent blowholes in the weld deposit. Before welding remove oil and grease. Clean weld area by gouging or grinding to remove cracks or worn fatigued surface of components. Use electrode on AC/DC+ at the lowest amps. Electrode can be weaved 2.0 to 2.5 times its diameter. Peen deposits while hot. High carbon steel base metal to be preheated to 250°C. For higher build up on carbon or high alloy steels use 6609L as a cushioning layer. For manganese steels, restrict heat build up to 150°C and use 6618/ 700MN alloy if necessary as a cushion layer. No preheat should be used on manganese steel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Welding Rod Category

Non-Machinable Low Heat Input Welding Electrode

Price 475 INR / Box

Minimum Order Quantity : 1 Box

Opening Pattern : AC

Welding Current : 40 250 A

Material : Cast Iron

Diameter : 2.5 5 Millimeter (mm)

Low Heat Type Contact Welding Electrode

Minimum Order Quantity : 1 Box

Opening Pattern : AC

Welding Current : 45 210 A

Material : Mild Steel

Diameter : 2.5 5 Millimeter (mm)

Low Heat Input minimal dilution Cast Iron Welding Electrode

Price 270 INR / Box

Minimum Order Quantity : 1 Box

Opening Pattern : AC

Welding Current : 60170 Amps

Material : Cast Iron

Diameter : 2.5 5 Millimeter (mm)

1006 Hardfacing Welding Electrode

Price 346 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Opening Pattern : AC

Welding Current : 180 210

Material : stainless steel

Diameter : 2.5 5 Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese