CR60 Rail Dimensions

CR60 Rail Dimensions Specification

- Product Name

- Steel Products

- Steel Type

- Mild Steel

- Steel Product Type

- Steel Rails

- Grade

- Stainless steel 202/304 grade

- Surface

- Checkered

- Application

- Construction

- Dimension (L*W*H)

- OD = 374 mm & H= 816mm Sheet thickness = 1.2 mm Millimeter (mm)

- Weight

- 40 Kilograms (kg)

CR60 Rail Dimensions Trade Information

- Minimum Order Quantity

- 10 Tons

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About CR60 Rail Dimensions

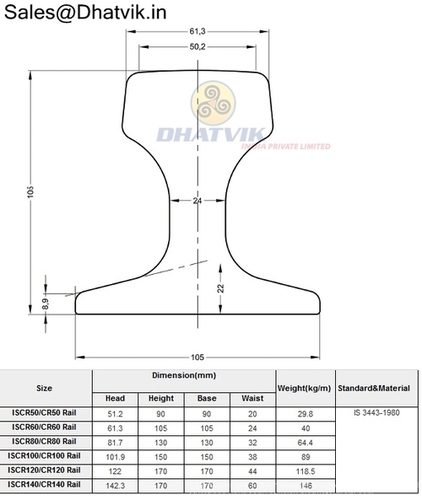

CR60 Rail, also known as 60 kg/m rail, is a heavy-duty steel rail widely used in railway tracks for freight and passenger transport. Designed for strength, stability, and durability, CR60 rails are manufactured as per international railway standards. With a head width, height, and base width engineered for heavy loads, these rails ensure safe and efficient train operations. The standard CR60 rail dimensions provide excellent resistance to wear and tear, making them ideal for high-speed, heavy-load railway tracks, industrial rail lines, and mining applications.

Specifications ofCR60 Rail Dimensions:

- Rail Designation:CR 60 Rail

- Rail Origin:India

- Standard:IS 3443-1980

- Area of crane rail section:5099 mm2

- CR60 Rail Weight:40 kg/m

- Neutral Axis to base:50.8 mm

FAQs of CR60 Rail Dimensions:

Q1. What are the standard dimensions of a CR60 Rail?

A: The CR60 Rail has a weight of 60 kg per meter with dimensions approximately 172 mm in height, 75 mm head width, 150 mm base width, and a 16.5 mm web thickness.

Q2. Where are CR60 Rails commonly used?

A: CR60 Rails are widely used in mainline railway tracks, metro systems, heavy-haul freight lines, mining railways, and industrial sidings.

Q3. What material is used for CR60 Rail manufacturing?

A: CR60 Rails are manufactured using high-quality carbon steel or manganese steel, ensuring superior strength, toughness, and long service life.

Q4. Why are CR60 Rail dimensions important?

A: Accurate CR60 Rail dimensions are crucial for maintaining stability, ensuring smooth wheel movement, reducing wear, and providing long-term performance in railway infrastructure.

Q5. Can CR60 Rails be customized?

A: Yes, CR60 Rails can be manufactured and supplied according to different lengths, drilling requirements, and finishing standards as per project needs.

Superior Material and Strength

Built with high-grade stainless steel (202/304), CR60 Rail offers excellent corrosion resistance and structural integrity. The checkered finish adds a practical touch, improving anti-slip properties and durability, especially in heavy-duty construction scenarios. This combination ensures the rail stands up to harsh outdoor environments.

Optimal Dimensions for Construction

The CR60 Rails measured outer diameter of 374 mm, height of 816 mm, and a sheet thickness of 1.2 mm meet industry requirements for stability and load-bearing capacity. These dimensions make the rail versatile for various construction projects, including scaffolding, platforms, and walkways.

FAQs of CR60 Rail Dimensions:

Q: How is the CR60 Rail utilized in construction projects?

A: The CR60 Rail is primarily used in construction for creating robust frameworks, scaffolding, and platforms. Its checkered surface provides added traction, making it suitable for walkways and areas requiring enhanced grip and safety.Q: What grade of steel is used in the manufacturing of CR60 Rail?

A: The CR60 Rail is manufactured using stainless steel grades 202 and 304. These grades offer superior strength and resistance to corrosion, ensuring long-term reliability in demanding environments.Q: When should a construction project consider using the CR60 Rail?

A: Projects requiring durable and safe steel components, especially where stability and anti-slip features are crucial, should consider the CR60 Rail. Its checkered surface and solid dimensions make it ideal for high-traffic or load-bearing applications.Q: Where is the CR60 Rail exported and supplied from?

A: The CR60 Rail is exported and supplied by manufacturers, exporters, and service providers located in India. They offer international distribution to meet the needs of construction projects globally.Q: What is the process for manufacturing the CR60 Rail?

A: The rail is manufactured by processing stainless steel sheets of specified grades and thickness. The sheets are formed into the required dimensions and finished with a checkered surface, ensuring quality, accuracy, and safety features.Q: What are the main benefits of using CR60 Rails in construction?

A: Utilizing CR60 Rails provides enhanced corrosion resistance, structural strength, and improved safety due to the checkered surface. These rails contribute to longer asset life, reduced maintenance, and a safer work environment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Rod Category

Chrome Plated Rod

Minimum Order Quantity : 1 2 Number

Grade : Stainless steel 202/304 grade

Product Name : Steel Products

Dimension (L*W*H) : OD = 110 mm & H= 100mm ID=25.5mm Millimeter (mm)

Application : Construction

Stainless Steel Single Pole Double Dustbin

Price 5000 INR / Number

Minimum Order Quantity : 5

Grade : Stainless steel 202/304 grade

Product Name : Steel Products

Dimension (L*W*H) : OD = 374 mm & H= 816mm Sheet thickness = 1.2 mm Millimeter (mm)

Application : Other

BS 75R Rail

Price 90 INR / Metric Ton

Minimum Order Quantity : 01 Kilograms

Grade : Stainless steel 202/304 grade

Product Name : Steel Products

Dimension (L*W*H) : OD = 110 mm & H= 100mm ID=25.5mm Millimeter (mm)

Application : Construction

RAIL 90 LBS

Price 270 INR / Kilograms

Minimum Order Quantity : 1 Ton

Grade : Stainless steel 202/304 grade

Product Name : Steel Products

Dimension (L*W*H) : OD = 110 mm & H= 100mm ID=25.5mm Millimeter (mm)

Application : Construction

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese